Tutti i prezzi pubblicati sono in Euro ed IVA esclusa.

Tutti i prezzi pubblicati sono in Euro ed IVA esclusa

-

INFO

INFO

INFO

INFO -

€ 0,00

-

RICERCA

-

FILTRA CATEGORIE

-

CATEGORIE

-

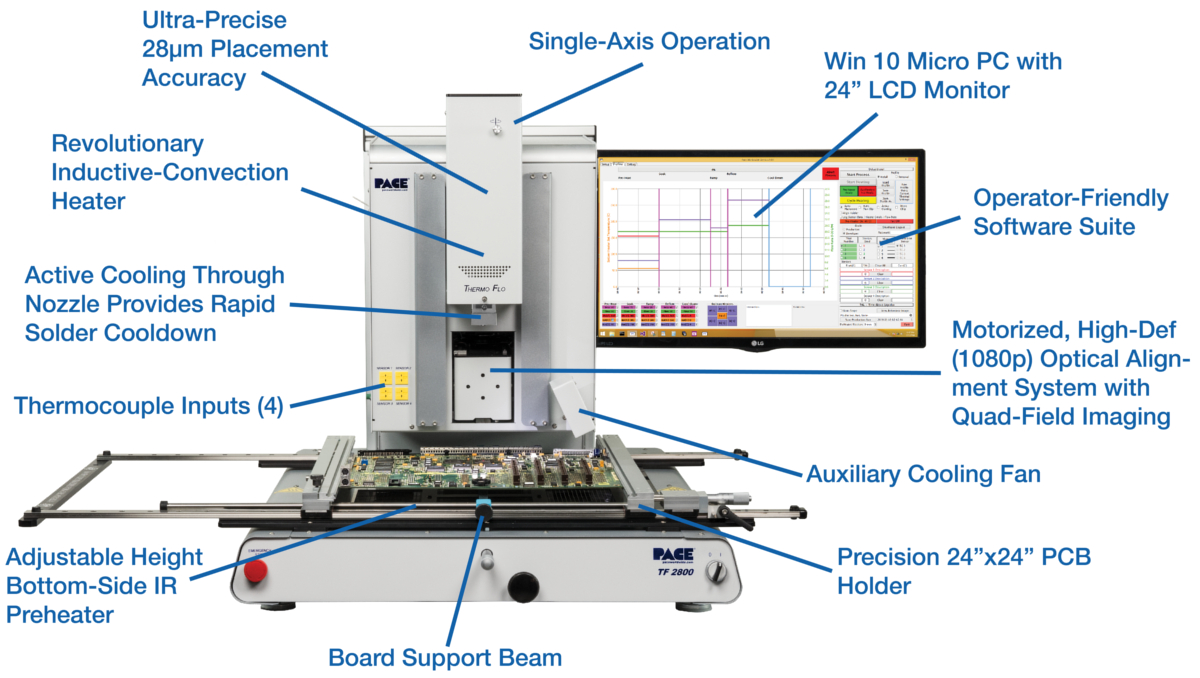

Pace TF2800 - Sistema rilavorazione componenti BGA e SMD

PACE TF2800 - Sistema per rilavorazione di componenti BGA e SMD.

PACE TF2800 - Sistema rilavorazione componenti BGA e SMD

With its groundbreaking, patent-pending Inductive-Convection Heating Technology, the TF 2800’s top-side heater reaches the target temperature in just seconds for safe, rapid solder joint reflow in virtually any component installation or removal application.

Features

- Ultra-Precise 28µm Placement Accuracy

- Revolutionary Inductive-Convection Heater

- Active Cooling Through Nozzle Provides Rapid Solder Cooldown

- 4 Thermocouple Inputs

- Adjustable Height Bottom-Side IR Preheater

- Board Support Beam

- Precision 24" x 24" PCB Holder

- Auxiliary Cooling Fan

- Motorized, High-Def (1080p) Optical Alignment System with Quad-Field Imaging

- Single-Axis Operation

- Windows 10 Micro PC with 24" LCD Monitor

- Operator-Friendly Software Suite

- Made in the USA

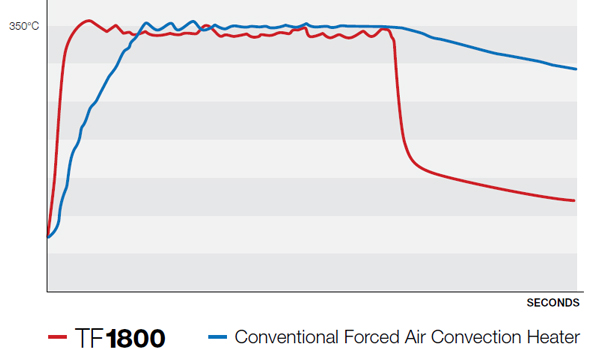

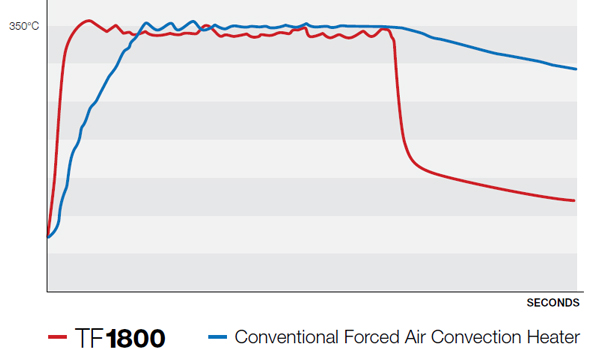

Top-Side Heater: Fast Heat Up - Rapid Cool Down

PACE’s Inductive-Convection Heater easily outperforms competitive heaters which utilize standard forced air convection technology, achieving target temperature instantaneously, about 4x faster than competitive heaters. Unlike conventional heaters, the TF 2800 immediately drops to temperatures well below solder melt when the heater is de-energized (results shown for TF 1800 Heater).

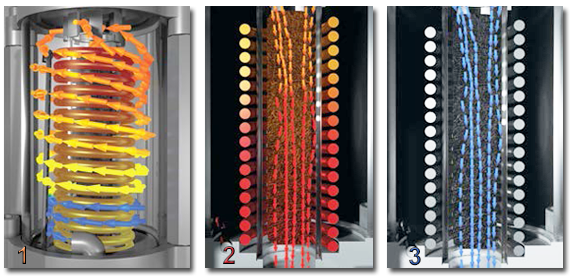

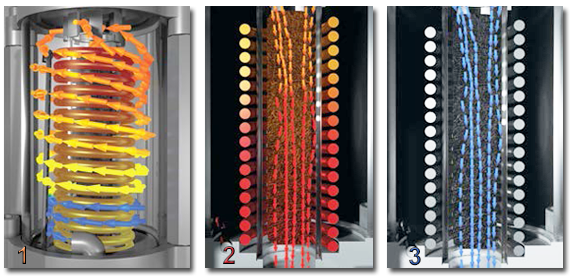

How Inductive-Convection Heating Works

The TF 2800’s patented Inductive-Convection Heating Technology provides ultimate thermal performance by its ability to instantly heat up and cool down the temperature of the air it delivers to the work.

- The air is first pre-heated in the outer heater chamber as it moves in a cyclonic fashion around the induction coil before it enters the inner chamber.

- After entering the inner chamber, the pre-heated air is then heated to target temperature through a highly efficient heat transfer process in an energized induction field.

- During active cooling, the induction coil is de-energized and the TF 2800 delivers fast, controlled, active cooling of the component and PCB directly through the nozzle, eliminating the risk of excessive intermetallic growth and yielding the highest quality solder joints.

Powerful, Energy Efficient Performance

The TF 2800’s Inductive-Convection Heating Technology delivers all the power you need to tackle the most challenging high thermal mass PCBs available today. Yet, its highly-efficient design does it with just a fraction of the power required by yesterday’s conventional heating technology.

Advanced Features

Chip Installation with TF2800 Rework Station:

Contattaci:

ALLEGATI

SCHEDA PRODOTTO

PACE TF2800 - Sistema rilavorazione componenti BGA e SMD

With its groundbreaking, patent-pending Inductive-Convection Heating Technology, the TF 2800’s top-side heater reaches the target temperature in just seconds for safe, rapid solder joint reflow in virtually any component installation or removal application.

Features

- Ultra-Precise 28µm Placement Accuracy

- Revolutionary Inductive-Convection Heater

- Active Cooling Through Nozzle Provides Rapid Solder Cooldown

- 4 Thermocouple Inputs

- Adjustable Height Bottom-Side IR Preheater

- Board Support Beam

- Precision 24" x 24" PCB Holder

- Auxiliary Cooling Fan

- Motorized, High-Def (1080p) Optical Alignment System with Quad-Field Imaging

- Single-Axis Operation

- Windows 10 Micro PC with 24" LCD Monitor

- Operator-Friendly Software Suite

- Made in the USA

Top-Side Heater: Fast Heat Up - Rapid Cool Down

PACE’s Inductive-Convection Heater easily outperforms competitive heaters which utilize standard forced air convection technology, achieving target temperature instantaneously, about 4x faster than competitive heaters. Unlike conventional heaters, the TF 2800 immediately drops to temperatures well below solder melt when the heater is de-energized (results shown for TF 1800 Heater).

How Inductive-Convection Heating Works

The TF 2800’s patented Inductive-Convection Heating Technology provides ultimate thermal performance by its ability to instantly heat up and cool down the temperature of the air it delivers to the work.

- The air is first pre-heated in the outer heater chamber as it moves in a cyclonic fashion around the induction coil before it enters the inner chamber.

- After entering the inner chamber, the pre-heated air is then heated to target temperature through a highly efficient heat transfer process in an energized induction field.

- During active cooling, the induction coil is de-energized and the TF 2800 delivers fast, controlled, active cooling of the component and PCB directly through the nozzle, eliminating the risk of excessive intermetallic growth and yielding the highest quality solder joints.

Powerful, Energy Efficient Performance

The TF 2800’s Inductive-Convection Heating Technology delivers all the power you need to tackle the most challenging high thermal mass PCBs available today. Yet, its highly-efficient design does it with just a fraction of the power required by yesterday’s conventional heating technology.

Advanced Features

Chip Installation with TF2800 Rework Station:

POTREBBERO INTERESSARTI ANCHE...

Scegli

Scegli

-

THEMEROLLER

-

INFO

-

IL MIO CARRELLOCarrello vuoto

-

- Richiedi informazioni: commerciale@cepeitalia.it

Salva nei preferiti

Salva nei preferiti

Invia link

Invia link